Thomas Newcomen’s atmospheric engine, developed in 1712, was the first practical steam engine. Its primary purpose was to pump water out of deep mines. The engine’s operation was based on the principle of creating a vacuum in a cylinder, which allowed atmospheric pressure to move a piston.

Table of Contents

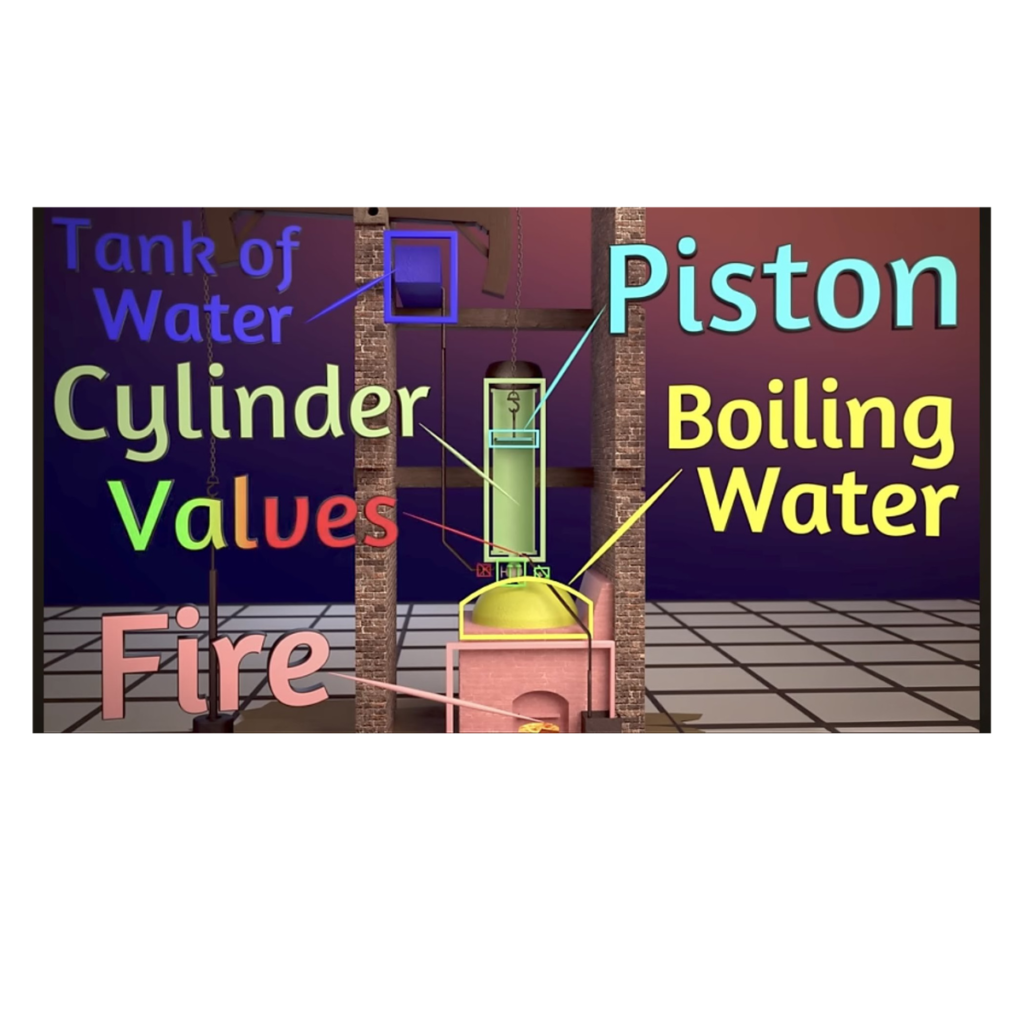

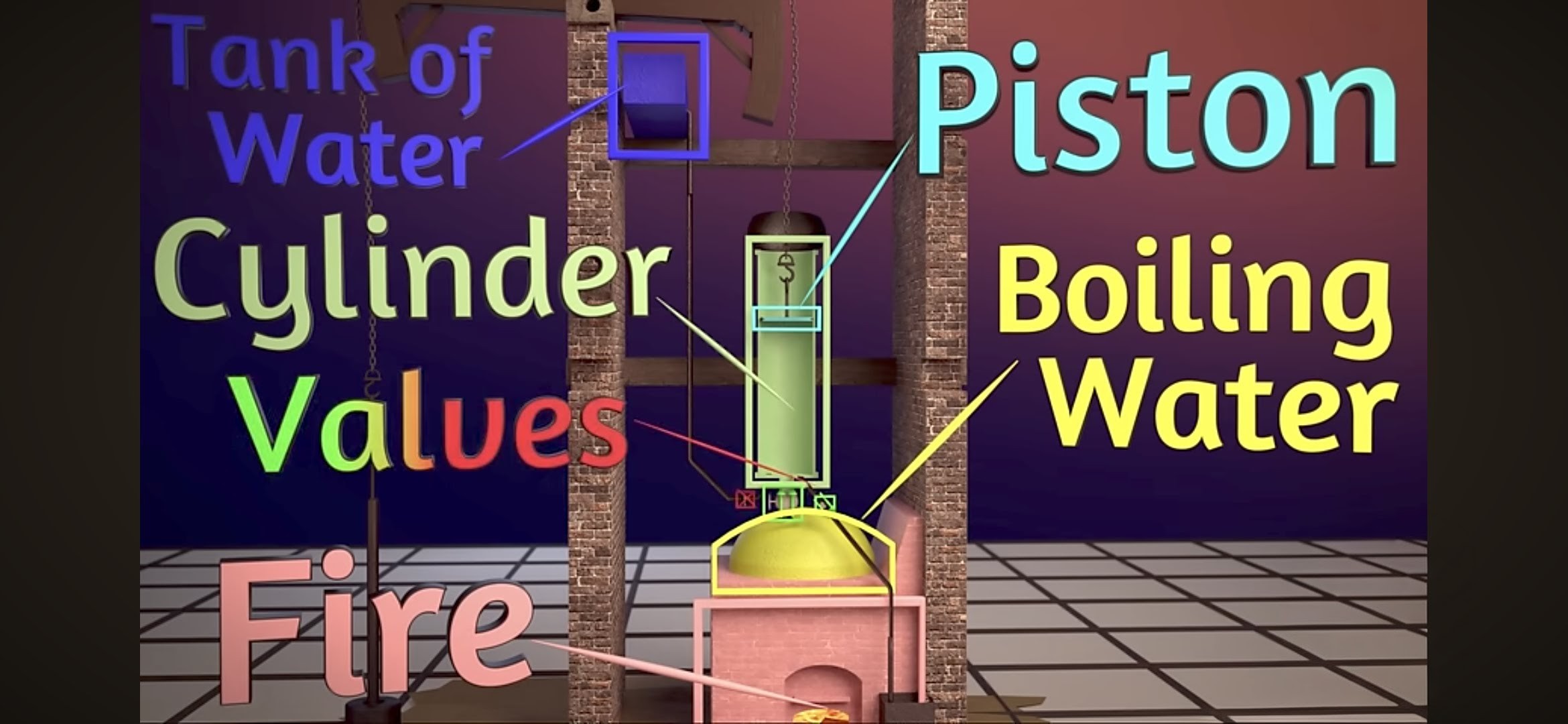

Components of the Engine

- Boiler:The boiler is a large vessel where water is heated to produce steam. This steam is the engine’s driving force. The boiler is typically heated by burning coal, which was abundant and cheap in England at the time.

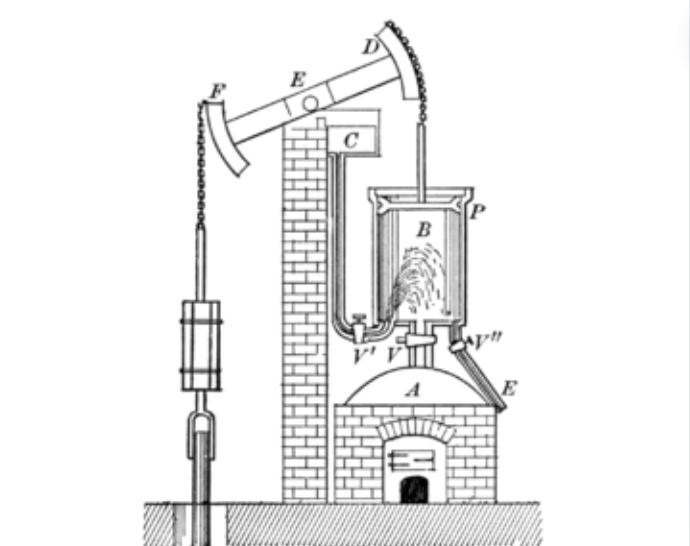

- Cylinder and Piston:The cylinder is a large, vertical metal tube that houses the piston. The piston is a solid disc that fits snugly inside the cylinder and moves up and down as steam is introduced and condensed. The piston is connected to one end of a large, pivoting beam.

- Beam:The beam is a large horizontal structure that central fulcrum movement. One end of the beam is connected to the piston connector, while the other end is connected to a pump connector. The beam translates the vertical movement of the piston into the mechanical action.

- Pump connector:The pump connector is attached to the end of the beam opposite the piston. As the beam moves up and down, the pump connector moves in a parallel motion.

- Injection Valve:This valve controls the injection of cold water into the cylinder. The injection of cold water is critical to the engine’s operation because it rapidly condenses the steam inside the cylinder, creating a vacuum.

- Snifting Valve :The snifting valve allows air and any other non-condensable gasses to escape from the cylinder. This ensures that the vacuum created by the condensing steam is as strong as possible.

1. Filling the Cylinder with Steam

The operation begins with the boiler heating water to produce steam. The steam is directed from the boiler into the cylinder using steam valve. When the steam valve opens, the cylinder fills with steam, pushing the piston upwards. As the piston rises, it pulls other end of the beam down, lifting the another end upwards.

2. Condensing the Steam

Once the piston reaches the top of its stroke, the steam valve is closed, isolating the steam inside the cylinder. At this point, the injection valve is opened, allowing cold water to spray into the cylinder.The cold water rapidly condenses the steam, turning it back into water. This condensation process causes a dramatic reduction in pressure inside the cylinder because steam occupies much more volume than water.

3. Creating the Vacuum:

As the steam condenses, a vacuum is created in the cylinder. The pressure inside the cylinder drops to a level much lower than atmospheric pressure. Science the piston is now exposed to near-atmospheric pressure on its upper side and a vacuum on its lower side, atmospheric pressure pushes the piston down with considerable force.

4. Power Stroke

The downward movement of the piston is the power stroke of the engine. As the piston descends, it pulls down the end of the beam connected to the piston rod. The other end of the beam, connected to the pump rod, rises, lifting water from the mine. This movement is what performs the useful work of the engine—pumping water from the depths of the mine to the surface.

5. Resetting the Cycle

Once the piston reaches the bottom of its stroke, the injection valve closes, and the snifting valve opens to allow any other gasses to escape from the cylinder.The steam valve then opens again, introducing fresh steam into the cylinder and pushing the piston back up to start the cycle.

Technical Innovations and Efficiency Considerations

Newcomen’s engine was a major advancement over previous attempts to use steam for mechanical work, particularly the work of Thomas Savery, who developed an earlier but less efficient steam pump. Here are some of the key technical aspects that made Newcomen’s engine a success:

- Vacuum-Based Operation:

Unlike Savery’s pump, which used steam pressure directly, Newcomen’s engine relied on creating a vacuum to harness atmospheric pressure. This method allowed for greater control and power, as the atmospheric pressure could be consistently applied to the piston.

- Condensation Process:

The rapid condensation of steam inside the cylinder was crucial for creating the vacuum. By injecting cold water directly into the cylinder, Newcomen was able to condense the steam quickly and effectively, creating a strong vacuum that atmospheric pressure could act upon.

- Beam Engine Design:

The pivoting beam was an ingenious solution for converting the linear motion of the piston into the reciprocal motion needed to drive a pump. This design also allowed the engine to be scaled up relatively easily by simply increasing the size of the beam, cylinder, and boiler.

- Challenges and Limitations:

Despite its success, Newcomen’s engine was not particularly efficient. It consumed large amounts of coal because the cylinder had to be reheated with each cycle after being cooled by the injection of cold water. This repeated heating and cooling led to significant energy losses.

- Application in Mining:

The primary application of Newcomen’s engine was in pumping water out of coal mines. Before its invention, mines were often flooded, limiting their depth and productivity. The Newcomen engine allowed mines to be dug deeper, significantly increasing coal production and fueling the growing industrial economy.

Evolution and Legacy

Newcomen’s atmospheric engine was widely adopted, particularly in England’s mining industry, and remained in use for several decades. However, its limitations in efficiency eventually led to further innovations.

In the 1760s, James Watt made significant improvements to Newcomen’s design. Watt introduced a separate condenser, which allowed the cylinder to remain hot while steam was condensed in a separate chamber. This innovation dramatically improved the engine’s efficiency by eliminating the need to repeatedly heat and cool the cylinder.

Watt’s improvements to the steam engine played a pivotal role in the Industrial Revolution, enabling the widespread use of steam power in factories, mills, and transportation.

Conclusion

Thomas Newcomen’s atmospheric engine represents a critical milestone in the history of technology. By successfully harnessing steam to create mechanical work, Newcomen laid the foundation for the Industrial Revolution and the modern world. His engine’s basic principles—using steam to create a vacuum and harnessing atmospheric pressure—were ingenious for their time and demonstrated the practical potential of steam power.

Although later advancements, particularly those by James Watt, would significantly improve the efficiency and applicability of steam engines, Newcomen’s work remains a landmark achievement in engineering. The atmospheric engine not only solved a pressing problem in mining but also opened the door to a new era of mechanization that would transform society in profound ways.

Pingback: Thomas Newcomen autobiography. Part 2